Cutlery production process

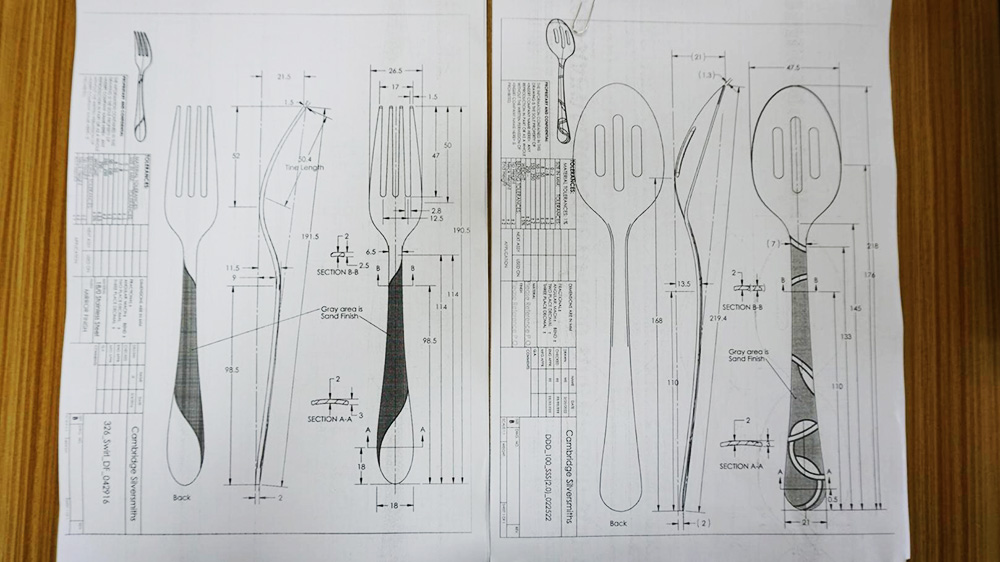

1. Design

OEM/ODM service, made matals according to your pictures(3d files), customed samples and detail requirements.

2. Raw Material

Stainless steel, generally have 18/10, 18/8, 18/0. (18/8 means that it contains 18 percent chrome, 8 percent nickel).

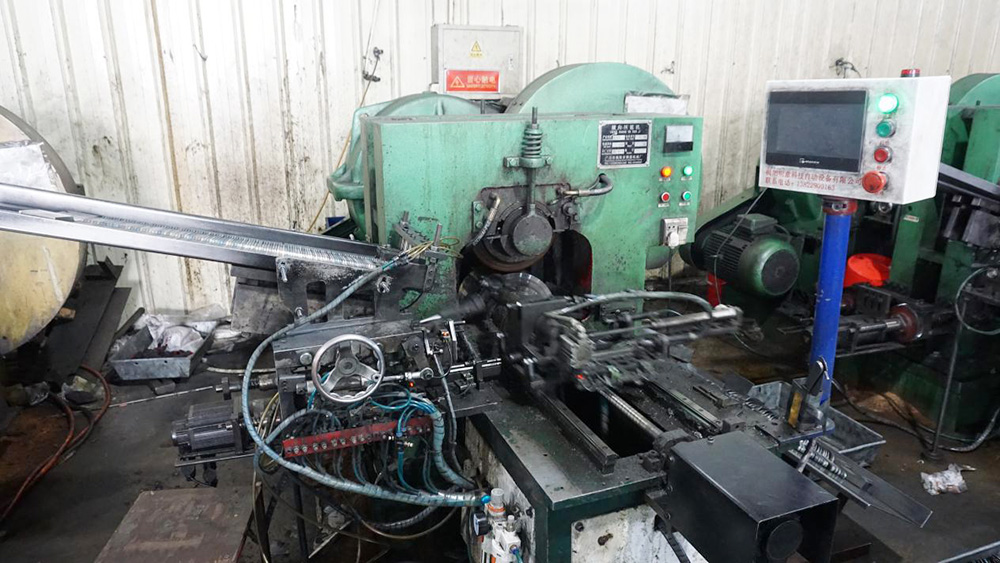

3. Stamping

Blanking, begin with flat blank of stainless steel by feeding a coil of sheet metal into a press and die.

4. Recycle Flattening

Through a series of rolling operations, these blanks are graded or rolled to the correct thickness and shapes required by the manufacturer’s flatware patterns.

5. Embossing

After heat treatment and trimming, the piece has a pattern embossed on it in a stamping operation.

6. Trimming Deflashing

The rolled blanks are placed in the cutout press by an operator, to remove the excess metal and to fashion the shape of the piece.

7. Edge Polishing

Trimming the edge to made it smooth, and this must ensure an accurate fit of the pieces into the dies when the design is applied.

8. Plat Polishing

Trimming and polish the edge again, let the edge not shape and smoother, safty to use it.

9. Punch Forming

The metal is squeezed into every tiny detail of the ornamentation in the die, embossing the pattern on the piece and squeezed a smooth spoon/fork curves shape.

10. Polishing

Give a bright, mirror-like finish, a soft, satiny glow, or a brushed finished.

11. Cleaning

12. QC

Inspection checks the pieces for chafes, scratches, rough spots between a fork’s tines, discoloration, or any other flaws that might have occurred when the pieces were stamped, shaped and polished.

13. Packing

Generally use opp bag to protect the face finished, for bulk order, we also can according to customers request.

14. Storage

Warehouse shown and the goods are prepare for shipping (Labeling is welcomed).